The use of peristaltic pumps in the mining industry

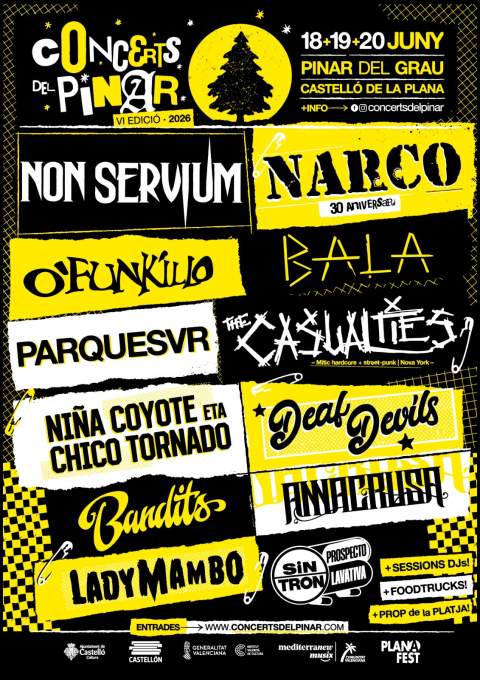

![[Img #61158]](upload/img/periodico/img_61158.jpg) The mining industry is a type of industrial and economic activity centred on the exploitation and extraction of metals and minerals that are underground in the shape of deposits. To be able to separate the land from the rock, to extract and to exploit different minerals and raw metals such as gold, copper, silver, mercury, coltan, platinum or tantalum, the mining sector uses specific machinery as the mining peristaltic pumps.

The mining industry is a type of industrial and economic activity centred on the exploitation and extraction of metals and minerals that are underground in the shape of deposits. To be able to separate the land from the rock, to extract and to exploit different minerals and raw metals such as gold, copper, silver, mercury, coltan, platinum or tantalum, the mining sector uses specific machinery as the mining peristaltic pumps.

The tasks in unfavourable conditions of work it´s one of the characteristics of the mining activity which multiplicity of present factors of risk they are inherent in the used technology, in the type and methods of work, in his development and in the type of exploitation. Peristaltic pumps are the first choice for mines around the world, offering unrivalled performance in a tough and uncompromising environment.

Which are the uses of mining peristaltic pumps?

Industrial peristaltic pumps have many applications in the mine:

Cyanide processing

Run dry

circulating slurry

Slurry transfer

Thickener underflow recirculation

Reagent dosing

Froth flotation

Their low shear capabilities deliver benefits when delivering polymers or flocculants in mining. Also, the peristaltic pumps are abrasion resistant and lower Maintenance Costs

In addition, being reversible and versatile offer a constant pumping in leaching and filtration tasks. In this way, costs are reduced and production is optimized.

Prior to the use of peristaltic mining pumps, centrifugal pumps were used for transferring solids such as zinc and lead. However, the high acidity of these metals weathered the rotors and impellers and the flow rates necessary to move the internal pulp were not reached.

![[Img #61159]](upload/img/periodico/img_61159.jpg) Thanks to the development of a good peristaltic pumps manufacturer, it has been possible to design industrial peristaltic pumps specific to this sector. Pumps peristaltic mining pumps have an inner hose that is the only element that is in counted with the pumped product.

Thanks to the development of a good peristaltic pumps manufacturer, it has been possible to design industrial peristaltic pumps specific to this sector. Pumps peristaltic mining pumps have an inner hose that is the only element that is in counted with the pumped product.

Mining peristaltic pumps are successfully used for cleaning reagents and chemicals. Mining peristaltic pumps prove their greatest effectiveness pumping highly concentrated solids and liquids.

In this way, it resists the abrasive effect coming from zinc, nickel or copper pulp, at the same time that it supports all kinds of cuts, extending its useful life. In addition, the hose can be changed quickly thanks to its easy design and placement.

Thanks to the easy installation and handling, it improves the cleaning tasks by reducing waste and not slowing down the stops. Unlike other progressive cavity pumps peristaltic mining pumps are able to pump minerals without modifying their properties working in different scenarios (mixing liquids and solids, high abrasive levels, aspiration of viscous products such as lime) regardless of pumping problems or obstructions.

The peristaltic pumps use lowly, less water and chemical and they can endure the terrible working conditions of mining. But the best of all their properties is that they are capable of pump toxic fluids gently and treat delicate minerals such as gold, silver, zinc or mercury.

![[Img #61158]](upload/img/periodico/img_61158.jpg) The mining industry is a type of industrial and economic activity centred on the exploitation and extraction of metals and minerals that are underground in the shape of deposits. To be able to separate the land from the rock, to extract and to exploit different minerals and raw metals such as gold, copper, silver, mercury, coltan, platinum or tantalum, the mining sector uses specific machinery as the mining peristaltic pumps.

The mining industry is a type of industrial and economic activity centred on the exploitation and extraction of metals and minerals that are underground in the shape of deposits. To be able to separate the land from the rock, to extract and to exploit different minerals and raw metals such as gold, copper, silver, mercury, coltan, platinum or tantalum, the mining sector uses specific machinery as the mining peristaltic pumps.

The tasks in unfavourable conditions of work it´s one of the characteristics of the mining activity which multiplicity of present factors of risk they are inherent in the used technology, in the type and methods of work, in his development and in the type of exploitation. Peristaltic pumps are the first choice for mines around the world, offering unrivalled performance in a tough and uncompromising environment.

Which are the uses of mining peristaltic pumps?

Industrial peristaltic pumps have many applications in the mine:

Cyanide processing

Run dry

circulating slurry

Slurry transfer

Thickener underflow recirculation

Reagent dosing

Froth flotation

Their low shear capabilities deliver benefits when delivering polymers or flocculants in mining. Also, the peristaltic pumps are abrasion resistant and lower Maintenance Costs

In addition, being reversible and versatile offer a constant pumping in leaching and filtration tasks. In this way, costs are reduced and production is optimized.

Prior to the use of peristaltic mining pumps, centrifugal pumps were used for transferring solids such as zinc and lead. However, the high acidity of these metals weathered the rotors and impellers and the flow rates necessary to move the internal pulp were not reached.

![[Img #61159]](upload/img/periodico/img_61159.jpg) Thanks to the development of a good peristaltic pumps manufacturer, it has been possible to design industrial peristaltic pumps specific to this sector. Pumps peristaltic mining pumps have an inner hose that is the only element that is in counted with the pumped product.

Thanks to the development of a good peristaltic pumps manufacturer, it has been possible to design industrial peristaltic pumps specific to this sector. Pumps peristaltic mining pumps have an inner hose that is the only element that is in counted with the pumped product.

Mining peristaltic pumps are successfully used for cleaning reagents and chemicals. Mining peristaltic pumps prove their greatest effectiveness pumping highly concentrated solids and liquids.

In this way, it resists the abrasive effect coming from zinc, nickel or copper pulp, at the same time that it supports all kinds of cuts, extending its useful life. In addition, the hose can be changed quickly thanks to its easy design and placement.

Thanks to the easy installation and handling, it improves the cleaning tasks by reducing waste and not slowing down the stops. Unlike other progressive cavity pumps peristaltic mining pumps are able to pump minerals without modifying their properties working in different scenarios (mixing liquids and solids, high abrasive levels, aspiration of viscous products such as lime) regardless of pumping problems or obstructions.

The peristaltic pumps use lowly, less water and chemical and they can endure the terrible working conditions of mining. But the best of all their properties is that they are capable of pump toxic fluids gently and treat delicate minerals such as gold, silver, zinc or mercury.